1995 Pontiac Trans Am - 1320Drag.net

#1

Thread Starter

GTcars - Post God !

iTrader: (1)

Joined: Mar 2005

Posts: 3,516

From: Toronto East

Rep Power: 0

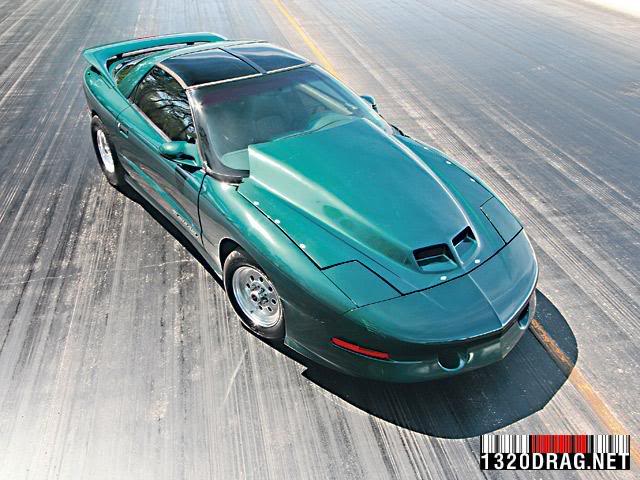

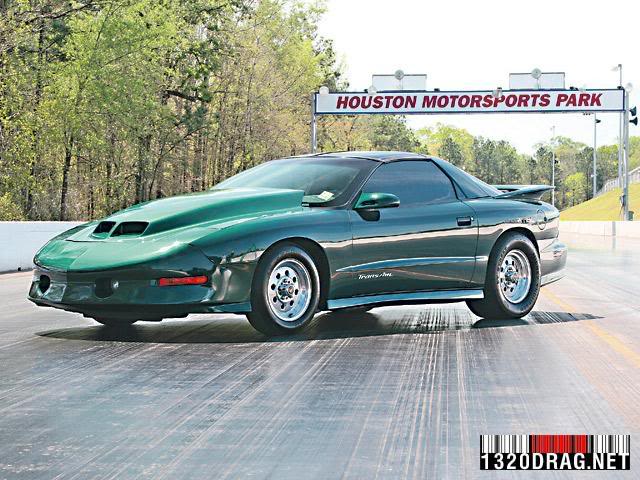

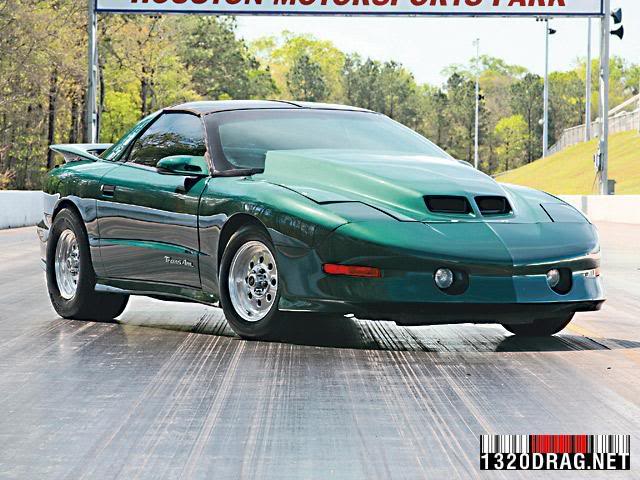

With A Little Ingenuity, This LT1 Firebird Goes 9s For Under $10,000 !!!!

Owner: Clint Schexnayder

Car: 1995 Trans Am

Block: LT1, 355 cubic inches

Compression ratio: 10.5:1

Heads: Trickflow LT4 ported and polished by Lloyd Elliot Portworks, 2.05 intake, 1.625 exhaust valves

Cam: COMP Cams hydraulic roller, 230/244 duration at .050, .544/.576-inch lift, 112 LSA

Pushrods: COMP Cams chrome moly

Rocker arms: Scorpion 1.6 ratio

Pistons: Lunati forged

Rings: Sealed Power

Crankshaft: Lunati forged

Rods: Eagle H-beam

Throttle body: BBK 58mm

Fuel injectors: Lucas, 83lb./hr.

Fuel pump: Stock with NOS 255lph inline

Ignition: Stock Optispark, MSD coil, MSD 6A ignition box

Engine management: Stock computer tuned by owner

Power adder: Nitrous Express 150-200hp shot

Exhaust system: Jet Hot long tube headers, X-pipe, 3-inch true dual exhaust with Dynomax bullet mufflers

Transmission: TH-350 built by Schexnayder Racing

Torque converter: Precision Industries 4000-stall

Driveshaft: Stock

Front suspension: BMR K-member, HAL/QA1 coilovers, stock control arms, removed swaybar

Rear suspension: Stock with polyurethane control arm bushings

Rear end: Ford 8.8-inch hybrid rear with stock GM 28-spline axles, 3.55 gear, posi

Brakes: Stock

Wheels: Weld 15x3.5 front, 15x10 rear

Front tires: M/T ET Front 26x4.5

Rear tires: M/T ET Street Radial 325/50R15

Fuel octane: 112

Race weight: 3,450 lbs.

Best ET/mph: 9.83 at 136

Best 60-ft. time: 1.48

Current mileage: 134,085

Miles driven weekly: 25

It's common knowledge that cars are one of the single worst investments you could ever purchase. As we drive them, modify them or race them, our hot rods are constantly decreasing in value. Even after pouring tens of thousands of dollars into one badass ride, it is still worth little more than its stock counterpart--and sometimes, even less! This is exactly what prompted Clint Schexnayder to take a more budget-minded approach on his '95 Trans Am.

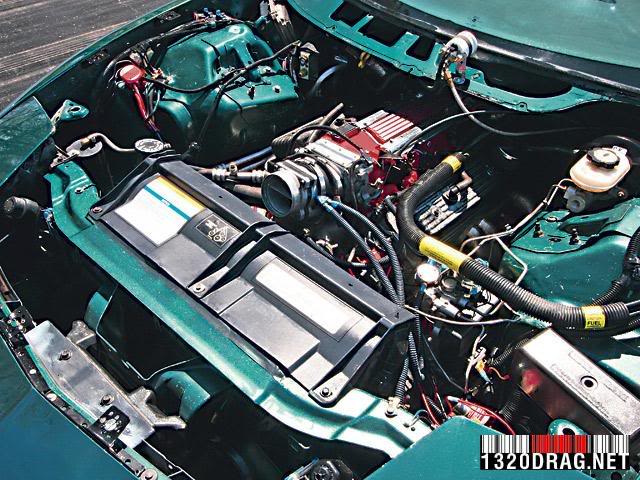

"I wanted a fast streetcar, built as cheap as I could, doing all the work myself. Of course it doesn't hurt when your brother has his own shop." Except for machining the block, which was taken to a local machine shop for a .030 over bore and line honed four-bolt splayed caps, the Louisiana native has stayed true to his word in devoting plenty of elbow grease to the project. With help from his brother, Clint checked the clearances before installing Clevite bearings and a Lunati 3.48 stroke forged steel crank. The Sealed Power rings were file-fit and inserted into the Lunati nitrous-friendly high compression pistons. Finally, a set of full floating pins connected Eagle H-beam rods to the forged pistons to complete the 355-cube LT1 bottom end.

Schexnayder had originally used a set of ported stock heads, which had kept compression at 11.5:1. However, when the stockers cracked, he purchased a set of bare Trickflow heads off the Internet for a mere $700. Lloyd Elliot Portworks made good use of the extra material used in the aftermarket head, and after the combustion chambers were reshaped and the runners expanded, Clint assembled the heads. COMP Cams 977 springs and Manley 2.05 intake and 1.625 exhaust valves would help take advantage of 217cc intake runners. Even after milling the heads, however, compression was dropped to 10.5:1. While probably not optimum for a naturally aspirated or nitrous LT1, it did make Clint's job of tuning the new combo a bit easier with TunerCat hooked up to the stock computer. And a large 230/244 duration, .544/.576-inch lift COMP CC306 nitrous cam presented enough of a challenge. Those figures, of course, factor in the Scorpion 1.6 ratio rocker arms, which Schexnayder uses in cooperation with a set of COMP Cams hardened pushrods.

The big cam is supplied with sufficient airflow via a fully ported and welded LT4 intake manifold, BBK 58mm throttle body, and a 150 to 200hp dose of nitrous. The wet-style Nitrous Express kit has recently been expanded from a single Shark nozzle to a dual nozzle, dual stage kit. Clint says he hasn't used the second stage yet, but it is wired in through a Digitech timer while the first stage operates at wide-open throttle. The stock injectors have so far proven sufficient with this combo, using only an NOS 255-lph inline fuel pump and Accel regulator to boost fuel pressure to 55 psi. Likewise, Clint uses the stock Optispark with an MSD Coil and 6A ignition box. Exhaust duties are carried out by a set of Jet Hot long tube headers and 3-inch true dual exhaust setup Clint welded up using a Summit Universal X-pipe kit and Dynomax bullet mufflers. So far, Clint had spent a few coins on his TA, but the real savings would come in the driveline and suspension. The Panhard bar has never been unbolted since he bought the car in December 1999, and the stock torque arm has likewise been left untouched. The stock control arms are also intact, though they now sport polyurethane bushings and have been boxed for extra support. The stock springs and shocks still hold up the rear, but Schexnayder did switch to HAL/QA1 adjustable coil-overs in the front along with a BMR K-member to make engine removal a bit easier. The front sway bar is removed for weight savings. With a completely stock rear and used TH350, which had little more than a shift kit, he managed to propel the 3,450-pound TA to a 10.20. However, after scoring a great deal on a used, fully built TH350 with a transbrake (built by his brother) a few changes would have to be made. The stock 7.625-inch 10-bolt with a failing posi would no longer be sufficient. Clint went to work on grafting the stock axle tubes onto the center section of a Ford 8.8-inch rear from an old LTD. The 8.8 went into the jig and the F-body axle tubes were welded up to it before fabricating the torque arm mount. The stock GM 28-spline axles went back into their respective tubes, engaging the used Ford 3.55s and rebuilt Traction-Lock.

Using a set of meaty 325/50R15 Mickey Thompson drag radials and a Precision Industries 4000-stall converter, Schexnayder's TA is now capable of 1.42 short times on the way to 9.83 at 136mph on juice. Clint states that most runs have been made with a 150-shot on pump gas, but a high-octane ****tail has allowed 20 or so runs with 175 to 200hp worth of laughing gas. On motor, performance is hurt by the large diameter tires and extra stiff valvesprings, forcing him to switch to 26x10-inch slicks and short shifting at around 6,000 rpm. Despite not being able to buzz the motor up to the usual 6,500-7,000rpm, Clint has still managed an 11.15 at 121. It's amazing what a little bit of cash and a lot of hard work can get you.

Owner: Clint Schexnayder

Car: 1995 Trans Am

Block: LT1, 355 cubic inches

Compression ratio: 10.5:1

Heads: Trickflow LT4 ported and polished by Lloyd Elliot Portworks, 2.05 intake, 1.625 exhaust valves

Cam: COMP Cams hydraulic roller, 230/244 duration at .050, .544/.576-inch lift, 112 LSA

Pushrods: COMP Cams chrome moly

Rocker arms: Scorpion 1.6 ratio

Pistons: Lunati forged

Rings: Sealed Power

Crankshaft: Lunati forged

Rods: Eagle H-beam

Throttle body: BBK 58mm

Fuel injectors: Lucas, 83lb./hr.

Fuel pump: Stock with NOS 255lph inline

Ignition: Stock Optispark, MSD coil, MSD 6A ignition box

Engine management: Stock computer tuned by owner

Power adder: Nitrous Express 150-200hp shot

Exhaust system: Jet Hot long tube headers, X-pipe, 3-inch true dual exhaust with Dynomax bullet mufflers

Transmission: TH-350 built by Schexnayder Racing

Torque converter: Precision Industries 4000-stall

Driveshaft: Stock

Front suspension: BMR K-member, HAL/QA1 coilovers, stock control arms, removed swaybar

Rear suspension: Stock with polyurethane control arm bushings

Rear end: Ford 8.8-inch hybrid rear with stock GM 28-spline axles, 3.55 gear, posi

Brakes: Stock

Wheels: Weld 15x3.5 front, 15x10 rear

Front tires: M/T ET Front 26x4.5

Rear tires: M/T ET Street Radial 325/50R15

Fuel octane: 112

Race weight: 3,450 lbs.

Best ET/mph: 9.83 at 136

Best 60-ft. time: 1.48

Current mileage: 134,085

Miles driven weekly: 25

It's common knowledge that cars are one of the single worst investments you could ever purchase. As we drive them, modify them or race them, our hot rods are constantly decreasing in value. Even after pouring tens of thousands of dollars into one badass ride, it is still worth little more than its stock counterpart--and sometimes, even less! This is exactly what prompted Clint Schexnayder to take a more budget-minded approach on his '95 Trans Am.

"I wanted a fast streetcar, built as cheap as I could, doing all the work myself. Of course it doesn't hurt when your brother has his own shop." Except for machining the block, which was taken to a local machine shop for a .030 over bore and line honed four-bolt splayed caps, the Louisiana native has stayed true to his word in devoting plenty of elbow grease to the project. With help from his brother, Clint checked the clearances before installing Clevite bearings and a Lunati 3.48 stroke forged steel crank. The Sealed Power rings were file-fit and inserted into the Lunati nitrous-friendly high compression pistons. Finally, a set of full floating pins connected Eagle H-beam rods to the forged pistons to complete the 355-cube LT1 bottom end.

Schexnayder had originally used a set of ported stock heads, which had kept compression at 11.5:1. However, when the stockers cracked, he purchased a set of bare Trickflow heads off the Internet for a mere $700. Lloyd Elliot Portworks made good use of the extra material used in the aftermarket head, and after the combustion chambers were reshaped and the runners expanded, Clint assembled the heads. COMP Cams 977 springs and Manley 2.05 intake and 1.625 exhaust valves would help take advantage of 217cc intake runners. Even after milling the heads, however, compression was dropped to 10.5:1. While probably not optimum for a naturally aspirated or nitrous LT1, it did make Clint's job of tuning the new combo a bit easier with TunerCat hooked up to the stock computer. And a large 230/244 duration, .544/.576-inch lift COMP CC306 nitrous cam presented enough of a challenge. Those figures, of course, factor in the Scorpion 1.6 ratio rocker arms, which Schexnayder uses in cooperation with a set of COMP Cams hardened pushrods.

The big cam is supplied with sufficient airflow via a fully ported and welded LT4 intake manifold, BBK 58mm throttle body, and a 150 to 200hp dose of nitrous. The wet-style Nitrous Express kit has recently been expanded from a single Shark nozzle to a dual nozzle, dual stage kit. Clint says he hasn't used the second stage yet, but it is wired in through a Digitech timer while the first stage operates at wide-open throttle. The stock injectors have so far proven sufficient with this combo, using only an NOS 255-lph inline fuel pump and Accel regulator to boost fuel pressure to 55 psi. Likewise, Clint uses the stock Optispark with an MSD Coil and 6A ignition box. Exhaust duties are carried out by a set of Jet Hot long tube headers and 3-inch true dual exhaust setup Clint welded up using a Summit Universal X-pipe kit and Dynomax bullet mufflers. So far, Clint had spent a few coins on his TA, but the real savings would come in the driveline and suspension. The Panhard bar has never been unbolted since he bought the car in December 1999, and the stock torque arm has likewise been left untouched. The stock control arms are also intact, though they now sport polyurethane bushings and have been boxed for extra support. The stock springs and shocks still hold up the rear, but Schexnayder did switch to HAL/QA1 adjustable coil-overs in the front along with a BMR K-member to make engine removal a bit easier. The front sway bar is removed for weight savings. With a completely stock rear and used TH350, which had little more than a shift kit, he managed to propel the 3,450-pound TA to a 10.20. However, after scoring a great deal on a used, fully built TH350 with a transbrake (built by his brother) a few changes would have to be made. The stock 7.625-inch 10-bolt with a failing posi would no longer be sufficient. Clint went to work on grafting the stock axle tubes onto the center section of a Ford 8.8-inch rear from an old LTD. The 8.8 went into the jig and the F-body axle tubes were welded up to it before fabricating the torque arm mount. The stock GM 28-spline axles went back into their respective tubes, engaging the used Ford 3.55s and rebuilt Traction-Lock.

Using a set of meaty 325/50R15 Mickey Thompson drag radials and a Precision Industries 4000-stall converter, Schexnayder's TA is now capable of 1.42 short times on the way to 9.83 at 136mph on juice. Clint states that most runs have been made with a 150-shot on pump gas, but a high-octane ****tail has allowed 20 or so runs with 175 to 200hp worth of laughing gas. On motor, performance is hurt by the large diameter tires and extra stiff valvesprings, forcing him to switch to 26x10-inch slicks and short shifting at around 6,000 rpm. Despite not being able to buzz the motor up to the usual 6,500-7,000rpm, Clint has still managed an 11.15 at 121. It's amazing what a little bit of cash and a lot of hard work can get you.

#3

Awesome F-body!!

Its a realistic build, and just goes to show you don't have to blow ur life savings to build a reliable fast ride...Although i think he went a bit extra in some areas for a "budget build"

Its a realistic build, and just goes to show you don't have to blow ur life savings to build a reliable fast ride...Although i think he went a bit extra in some areas for a "budget build"

Thread

Thread Starter

Forum

Replies

Last Post

Supra_RZ

Special Events and Meets

6

03-14-2007 09:35 PM

2TONE_93GT

Special Events and Meets

0

06-05-2006 07:40 PM

2TONE_93GT

Special Events and Meets

4

05-17-2006 08:25 PM

2TONE_93GT

Special Events and Meets

0

03-09-2006 06:38 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)